1

/

of

3

DC CUSTOMS AND FABRICATION LIMITED

HEATSHIELD THERMAL TIES 5/16" X 33" - BAG OF 50PCS - 830MM

HEATSHIELD THERMAL TIES 5/16" X 33" - BAG OF 50PCS - 830MM

Regular price

$479.95 NZD

Regular price

Sale price

$479.95 NZD

Unit price

/

per

Tax included.

Couldn't load pickup availability

Stainless-Steel Cable Ties That Can Take the Heat:

Every automotive enthusiast knows the header on a car/motorcycle is one of the hottest parts of the exhaust system. Insulating your exhaust system requires special materials that won’t melt - that’s where Heatshield Products comes in. Our stainless-steel header wrap ties are designed to withstand continuous temperatures of 1800°F and intermittent temperatures of 2000°F,& come in two different sizes to fit your vehicle’s special needs.

High-Strength Fasteners for High-Heat Applications:

Your header pipe can reach extreme temperatures that can decrease your fuel efficiency and put your vehicle’s wires and lines at risk. Increase your power & protect your engine components by keeping your thermal barriers and auto heat shields in place with durable, high-strength fasteners like our stainless-steel cable ties.

Our header wrap ties are made from heavy-duty metal designed to withstand heat without becoming damaged or melting. Our 5/16-inch-wide 316 stainless-steel header wrap ties have 45% more gripping power than our 3/16-inch-wide ties, ensuring your heat shield and thermal barriers stay in place when you need power and reliability the most.

Easy-Install in Seconds:

You don't need special tools, bands,& buckles to be installed. Simply pull the tail end through the head and tighten - Our cable ties also have smooth edges, can be handled easily, and maintain a low profile.

Features:

Continuous operating temperature of 1800F

Rugged stainless steel locking ties

Each tie is only 0.010" thick

The 0.31 wide tie features 45% more gripping power

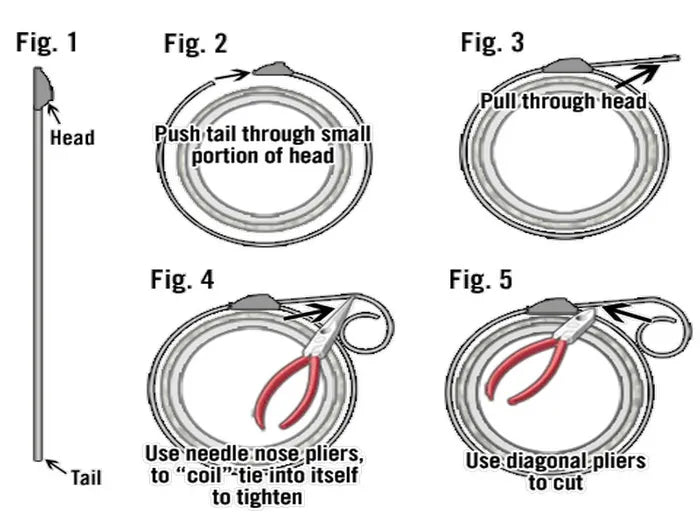

Installation Tips:

Equipment needed: gloves, needle nose pliers, and diagonal pliers

Identify the tail and heat of the stainless steel locking tie (Figure 1)

Wrap tie around components to be secured, and push tail through the head (Figure 2)

Pull tail through head (Figure 3)

Use needle nose pliers to coil or wind the tie into itself (Figure 4)

Use diagonal pliers to cut of excess (Figure 5)

Every automotive enthusiast knows the header on a car/motorcycle is one of the hottest parts of the exhaust system. Insulating your exhaust system requires special materials that won’t melt - that’s where Heatshield Products comes in. Our stainless-steel header wrap ties are designed to withstand continuous temperatures of 1800°F and intermittent temperatures of 2000°F,& come in two different sizes to fit your vehicle’s special needs.

High-Strength Fasteners for High-Heat Applications:

Your header pipe can reach extreme temperatures that can decrease your fuel efficiency and put your vehicle’s wires and lines at risk. Increase your power & protect your engine components by keeping your thermal barriers and auto heat shields in place with durable, high-strength fasteners like our stainless-steel cable ties.

Our header wrap ties are made from heavy-duty metal designed to withstand heat without becoming damaged or melting. Our 5/16-inch-wide 316 stainless-steel header wrap ties have 45% more gripping power than our 3/16-inch-wide ties, ensuring your heat shield and thermal barriers stay in place when you need power and reliability the most.

Easy-Install in Seconds:

You don't need special tools, bands,& buckles to be installed. Simply pull the tail end through the head and tighten - Our cable ties also have smooth edges, can be handled easily, and maintain a low profile.

Features:

Continuous operating temperature of 1800F

Rugged stainless steel locking ties

Each tie is only 0.010" thick

The 0.31 wide tie features 45% more gripping power

Installation Tips:

Equipment needed: gloves, needle nose pliers, and diagonal pliers

Identify the tail and heat of the stainless steel locking tie (Figure 1)

Wrap tie around components to be secured, and push tail through the head (Figure 2)

Pull tail through head (Figure 3)

Use needle nose pliers to coil or wind the tie into itself (Figure 4)

Use diagonal pliers to cut of excess (Figure 5)

Share